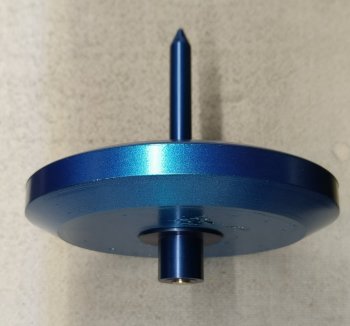

The bob is disk shaped with a diameter of 170 mm and a thickness of around 30 mm, for the most part made of lead and a targeted weight of 8 kg. It is chamferred on the edge to reduce air friction. In the center is an aluminium pully with a stem to connect to the wire and an insert with the magnet.

The bob was casted in an abandoned cooking pan, post-shaped on the lathe and spray-painted. The final bob has a weight of 6.9 kg.

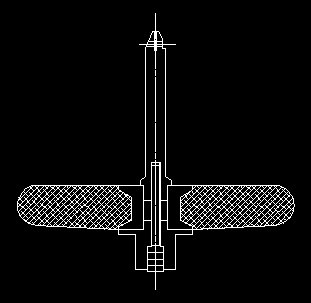

Fig 1. Drawing of the Bob.

Fig 2. Side view

Fig 3. Bottom with magnet holder

Fig 4. Stem, brass M6 rod, pully, insert, magnets.

Fig 5. Casting pan with pully, firmly screwed to the bottom.

A copper foil was inbetween to make it leak free.

Fig 6. Melting the lead.

Do this on a gas cooking plate. Electric plates may not produce enough heat and induction plates might be damaged by the high temperature.

Fig 7. Lead has been poured in.

Mind the tin and spoon on the left. I used it to skim oxidized lead and other dirt from the molten lead.

Fig 8. How it came out of the pan. Bottom side has several enclosures of oxidized lead and other dirt.

I decided to accept these irregularities.

Fig 9. On the lathe. Working with this material was a special experience, much different from other materials like aluminium, brass or steel. The chips coming off felt more like warm spaghetti and it is difficult to get a smooth, shiny surface. I used some sort of sanding sponge to smoothen the bob.

Fig 10. Enclosures visible. This is the bottom side. The top side is much better.

After machining the bob was spraypainted for a nice look. Bare lead becomes dull after some time.